“Replacement for Nordson EP10 Compatible Module” has been added to your cart. View cart

Replacement for Nordson 7162039 Speed-Coat® Control Module

$575.00

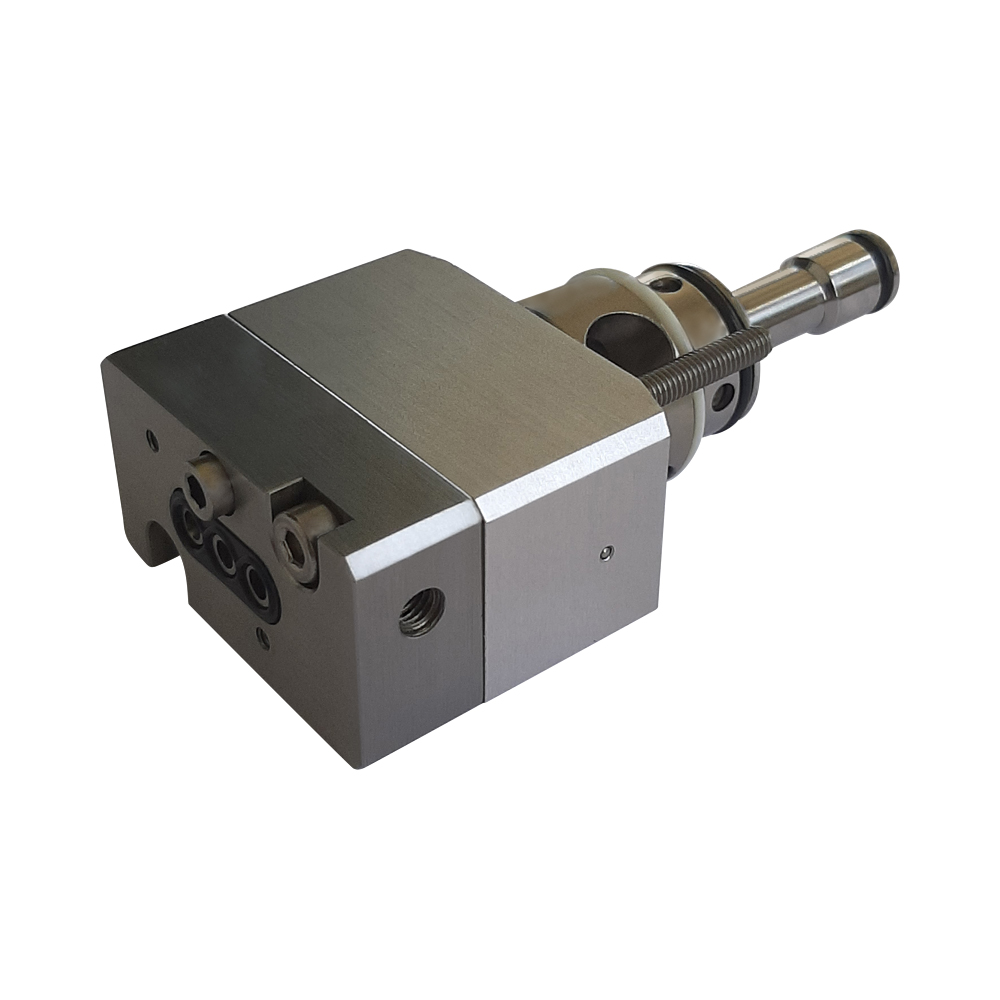

Glenmar GM62039 Module – direct replacement for Nordson® 7162039 Speed-Coat® Control Module. Engineered for precise hot melt application, designed for use within Universal platform applicators, and compatible with a range of Universal-style nozzles.

Order now for fast shipping!

SKU:

GM62039

Categories: Modules, Replacement for Nordson Nonwoven Parts, Replacement for Nordson Speed-Coat modules

Tag: G100B Module Replacement for Replacement for Nordson®

Description

Replacement for Nordson 7162039 Speed-Coat® Control Module

Looking for a direct replacement for Nordson 7162039? Glenmar Technology GM62039 Speed-Coat Module is the solution. This Universal Speed-Coat Module is a next-generation hot melt application system engineered to meet the toughest demands of today’s manufacturing environments. With a compact 25 mm module width, it offers the perfect balance of versatility and durability. Its robust construction ensures long-lasting reliability even under challenging production conditions, while its high cycle rate and precise adhesive control help manufacturers achieve consistent results with minimal downtime.

GM62039: A fully compatible replacement for Nordson® 7162039:

-

Direct Replacement for Nordson® 7162039: Engineered to meet OEM specifications for a perfect fit on Speed-Coat® Control Module, ensuring seamless integration with your existing system.

-

Precise Adhesive Flow Control: Speed-Coat Control allows accurate regulation of adhesive output, minimizing waste and ensuring consistent bonding quality.

-

Durable Industrial-Grade Materials: Manufactured from high-quality, heat-resistant, and wear-resistant materials for long-lasting performance in demanding production environments.

-

Universal Compatibility: High-performance replacement for Nordson Speed-Coat control module. Compatible with Universal applicators, it supports CF, Summit, SureWrap, Allegro, Control Coat, MiniBead, and Saturn nozzles.

-

Optimized Maintenance: Rebuildable module design helps reduce downtime and extends service life.

-

Cost-Efficient: The versatile design helps lower overall operational costs by minimizing inventory and reducing the number of required components.

Technical Specifications

Module Width: 25 mm compact design for seamless integration into existing systems while ensuring efficient space utilization in high-density production environments.

Nozzle Compatibility: Compatible with a wide range of 25 mm Universal nozzles; 22 mm Universal CF nozzles and adapters, allowing versatile dispensing options and reduced need for specialized components.

Operating Temperature Range: 70° to 205° C (160° to 400° F) – engineered for stable operation across a wide temperature spectrum, ensuring consistent adhesive performance in diverse manufacturing conditions.

Working Hydraulic Pressure: 13.8 to 55.2 bar (200 to 800 psi) – optimized for smooth adhesive flow and dependable performance under variable workloads.

Maximum Hydraulic Pressure: Withstands up to 89.6 bar (1300 psi), delivering reliable performance even in high-pressure applications without compromising durability.

Maximum Hydraulic Flow: 110 g/min at 10,000 centipoise , 14 g/m² at 300 m/min. This balance of flow capacity and precision makes the module ideal for both high-speed production and uniform adhesive application.

Actuation Air Pressure: Recommended at 4.1 bar (60 psi), ensuring fast, responsive actuation for reduced downtime and consistent adhesive patterns.

Cycle Rate: Capable of up to 9,000 cycles per minute or a rapid 24 ms on/off cycle, enabling high-speed production lines to maintain quality and output without interruption.

Solenoid & Power: Solenoid Voltage: 23.5 to 28 VDC, Solenoid Power Consumption: 5 watts, Solenoid Connection: Quick-disconnect with strain relief and LED indicator.

Additional Benefits

Handles Demanding High-Speed Intermittent Production: Perfect for high-speed, high-demand applications, ensuring smooth operation without compromise.

Improves Cutoff of Leading and Trailing Edges: Features a retract-on-close operation that enhances the precision and quality of adhesive application, particularly at the edges.

Reduces Maintenance Costs & Improves Service Life: With a rebuildable design, the GM48992 module helps reduce the need for costly replacements, extending the service life and reducing overall maintenance costs.

Minimizes Inventory Costs with Single-Platform Design: The versatile, single-platform design allows for easy compatibility with various dispensing technologies, helping to streamline inventory management and reduce costs.

Accepts Numerous Dispensing Technologies: Compatible with a wide range of dispensing technologies, making it adaptable to different production systems and requirements.

Why Choose GM62039?

Built with strict quality standards, GM62039 delivers reliable performance and seamless compatibility with Nordson 7162039. Order now for fast shipping!

Looking for reliable hot melt advice and parts? Glenmar Technology has you covered. Your needs, our priority. Visit us today and feel free to contact us.

Additional information

| Weight | 1.00 oz |

|---|---|

| Dimensions | 6.00 × 4.00 × 4.00 in |

| Type |

Nonwoven Speed-Coat Module |

| Nordson Compatibility |

Universal nozzles and adapters |

| Nordson Part Number |

7162039 |

| Glenmar Part Number |

GM62039 |

| Manufactured by |

Glenmar Technology |

| Country of Origin |

United States |

Reviews (0)

Be the first to review “Replacement for Nordson 7162039 Speed-Coat® Control Module” Cancel reply

Related products

1″ Swirl Brass Nozzle – G100FDSBRASS

$79.00

Glenmar Technology's G100FDSBRASS 1" Swirl Brass Nozzle is available in the following sizes: 0.014, 0.018, 0.035.

Select options

This product has multiple variants. The options may be chosen on the product page

Hose-222818 – Replacement for Nordson 222818 Hose Replacement

$2,100.00

ITW Dual Mini Gun Replacement – G300 Mini 2-Module Gun

$792.00

Replacement for Nordson 1035888 Summit Nozzle (Full Coverage) Ticn

$245.00

Replacement for Nordson 1048996 UM25 Standard Module

$350.00

Replacement for Nordson 7162040 SpeedCoat Applicator Control Module Replacement W/7157157 Solenoid Valve

$1,100.00

Replacement for Nordson EP11 Compatible Module

$630.00

Replacement ITW Mini Gun – G300 Mini Gun

$660.00

Reviews

There are no reviews yet.